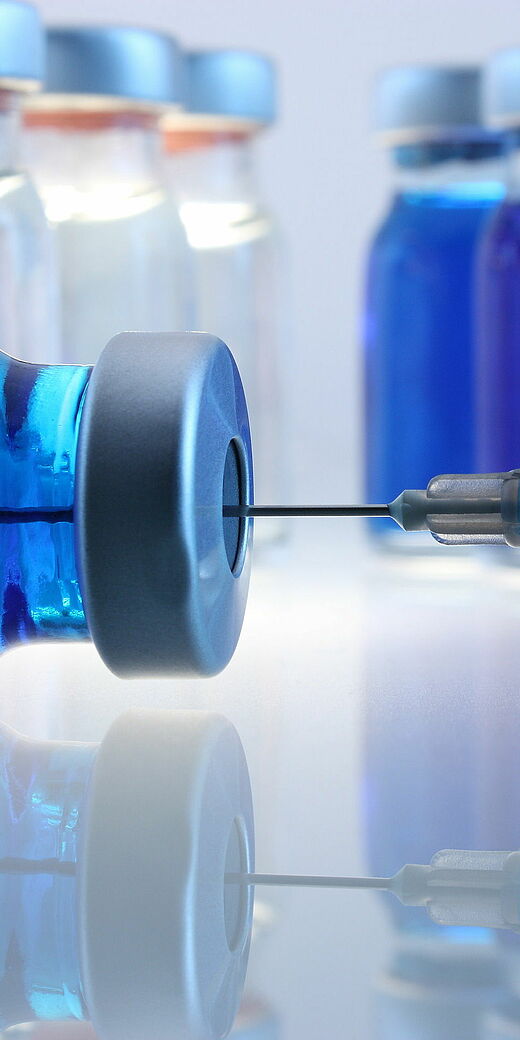

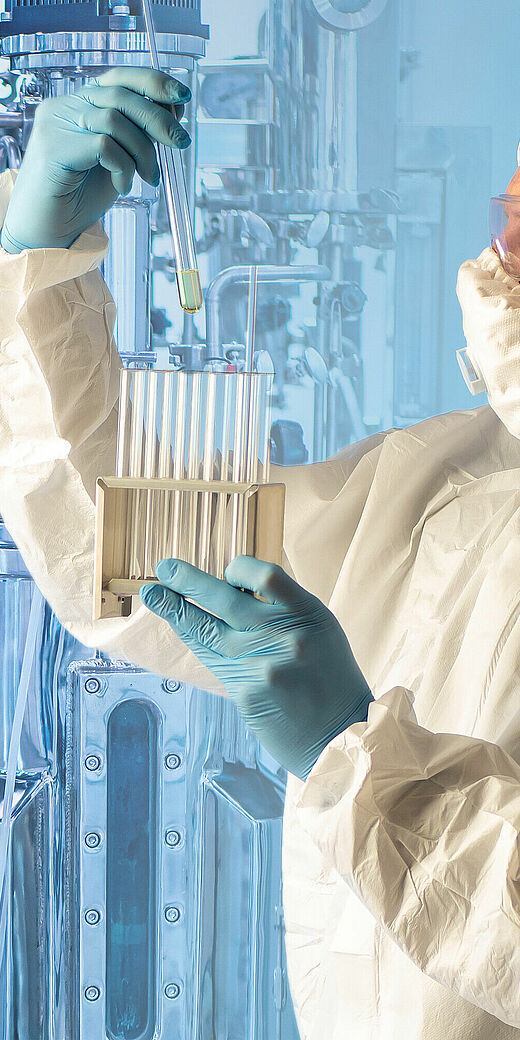

The potential risks of working and manipulating with pathogens, bacterial microorganisms and genetically modified organisms place high demands on containment, laboratory equipment and facilities, but also on infrastructure systems and sterility procedures.

Cleanroom Solutions from Ortner

We deal with all proven and innovative disinfection and decontamination processes used in pharmaceutical and BSL laboratories. Decontamination processes, starting with gassing processes, irradiation techniques, fogging processes, wet chemical processes up to the application of explosive media, are part of Ortners experise.

For years, we have been supporting pharmaceutical and biotech companies with innovative equipment, containment solutions and decontamination technologies so that they can master safe and high- quality manufacturing processes.

Print out

Print out