Through the additional use of mobile H₂O₂-catalysts, the necessary ventilation time can be reduced by up to 50 % for e.g. 1,000 m³ room volume.

Recirculation mode

The unit operates in recirculation mode. The gas is drawn in via the built- in catalyst, thus reducing the H₂O₂-concentration in the room.

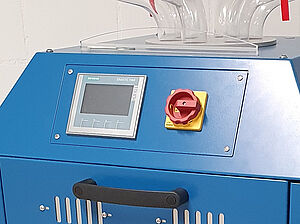

Operation via touch panel

The unit is operated via an integrated touch panel. Interfaces such as Profinet and potential- free contacts enable flexible use.

Autarkic operation

The unit is manufactured as a stand- alone unit and can be operated independently of the generator manufacturer.

Print out

Print out