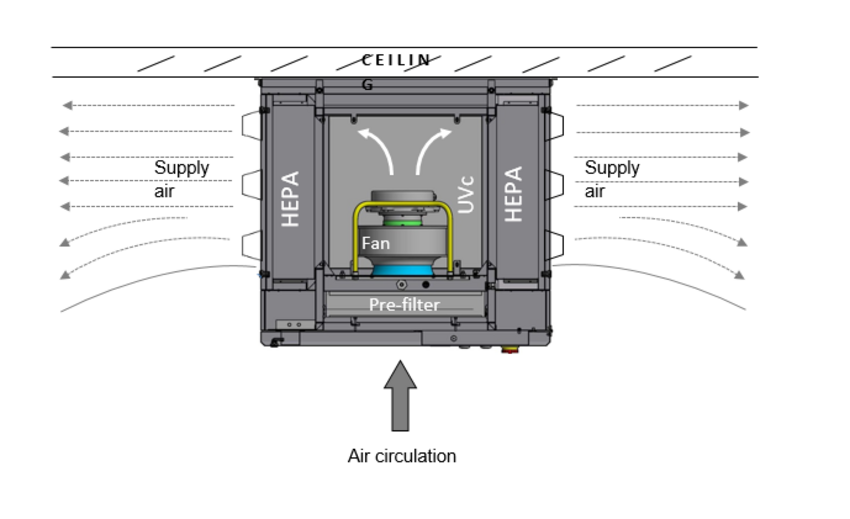

The particulate and microbiologically contaminated production air is sucked in by the hygiene cube, filtered free of particles and blown out sterilized by means of UVc irradiation. The design of the system allows the clean air to be discharged on one side, two, three or all four sides.

Hygiene Cube

To extend the shelf life of food

Simply clean, simply self- sufficient. Production facilities in the food industry are often difficult to keep completely germ- free. That is why Ortner has developed flexible equipment such as the Hygiene Cube. This is a self-sufficient unit for the permanent circulation of room air.

When the air becomes thinner... it also becomes cleaner with the Hygiene Cube from Ortner. In other words, clean room quality is achieved through the dilution principle. Due to their high air volume, the Hygiene Cubes are ideal for creating clean room or clean space requirements.

Areas of application range from small to large room volumes, from production rooms, logistics and transfer areas, pre-production, processing and primary packaging to cooling areas.

Ortner PLUS

- Established room protection concept for extending the shelf life of food products

- Low investment, low energy costs

- CFU < 50/ 100 m³ room volume achievable

- Microbiological safety through integrated UVc disinfection

- Internal surface disinfection prevents recontamination during production process

- Optional air discharge on one, two, three or four sides

- Ready- to- plug- in and factory- qualified system

- Complies with GMP and HACCP guidelines

Print out

Print out