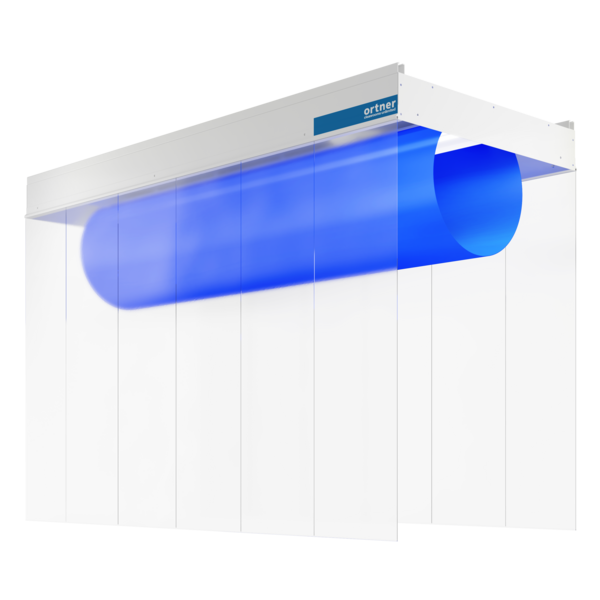

The PDc textile air hose system consists of a longitudinal support structure, equipped with fastening and mounting device, velcro fastener receptacle for the textile air hose and permanently installed lighting technology.

The air hose is simply mounted on the supporting structure and irradiated from the inside. Flexibility is ensured by special additional components such as bend elements, T- pieces, branches, connection systems and connecting elements.

Print out

Print out