- Safety and constant air quality throughout the production process

- Clean, low- germ environment- microbiologically as well as particulate safe

- Minimization of infrastructure investments and space requirements

- Reduction of energy costs and negative environmental impact

- Stable, consistent production conditions

- Demand- specific planning and conceptual design of cleanroom technology

Your Requirements

Ortner Solutions

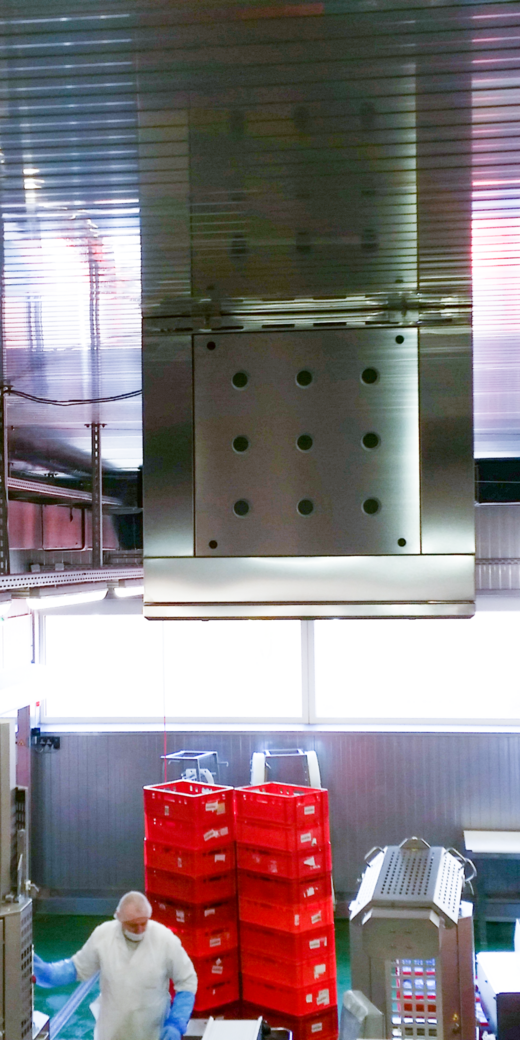

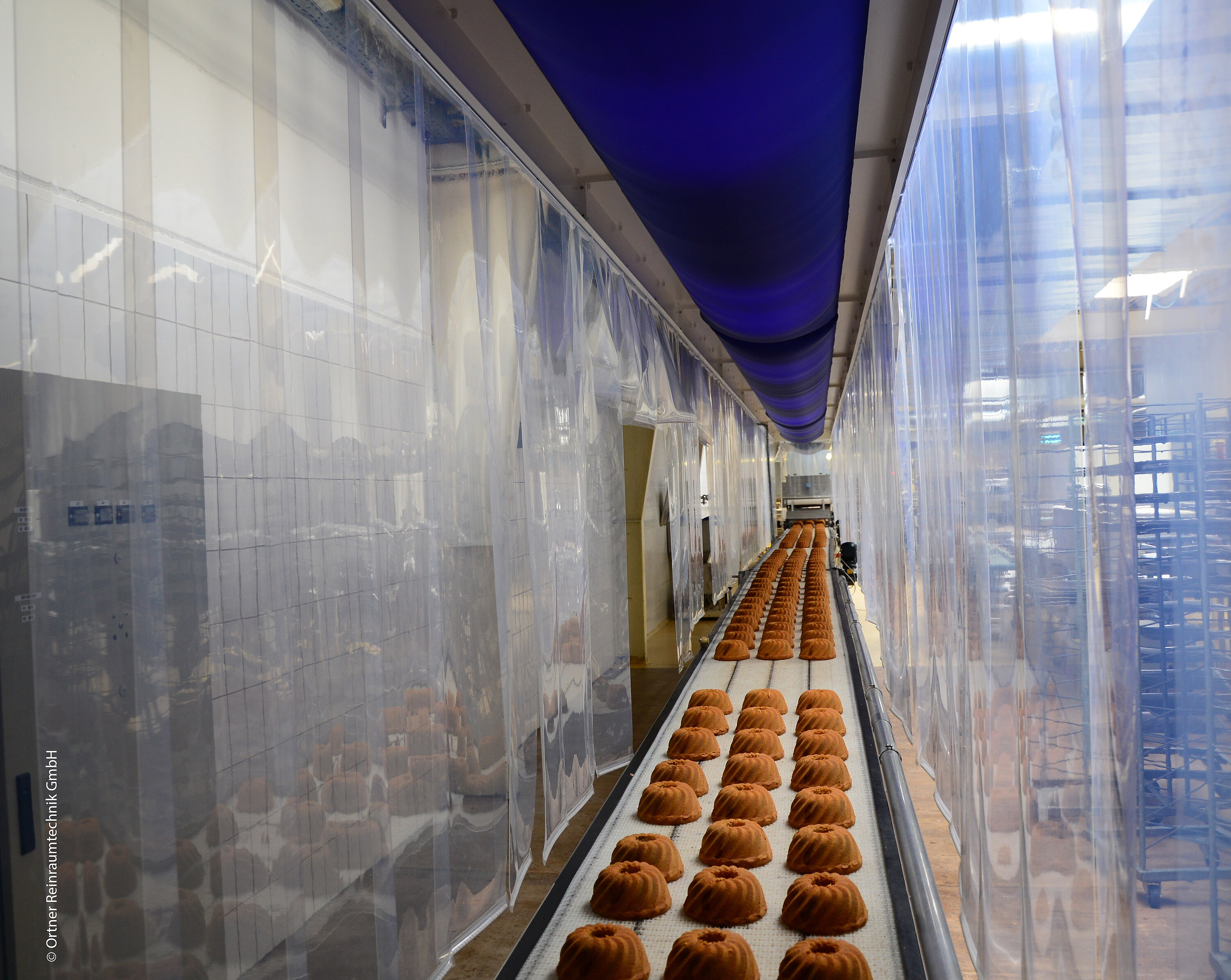

Clean air systems as room- integrated recirculating air filter protection systems or clean air room cooling systems for safe production processes that reduce infrastructure installations and minimize investments.

Air Protection Systems for Rooms

Every room, every manufacturing process and every work step has its specific cleanliness requirements.

The vast majority of cleanrooms are in the classification of ISO 6 to 8 and in the range of the term "cleanroom". These rooms are usually equipped by turbulent air filtration systems.

The goal is space- saving, energy- efficient infrastructure systems with compact technical control centers. In-room filter systems such as hygienic cubes or hygienic recirculating air coolers have proven their worth here.

The clean air is mostly produced directly in the room. The infrastructure systems are primarily responsible for fresh air and air conditioning.

Print out

Print out