Cytostatic isolators from Ortner ensure safe working conditions according to GMP Class A.

The special air guidance and handling via glove intervention guarantee safe separation of operator and process.

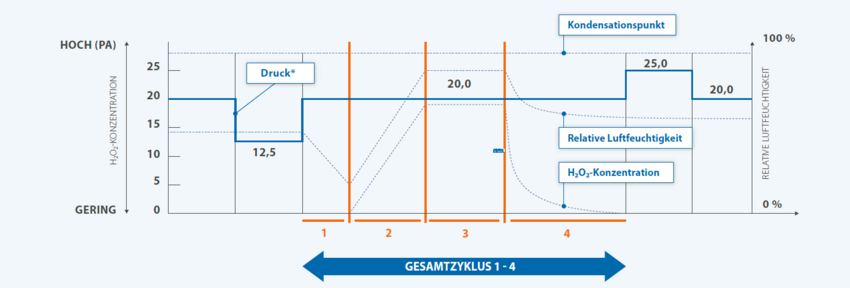

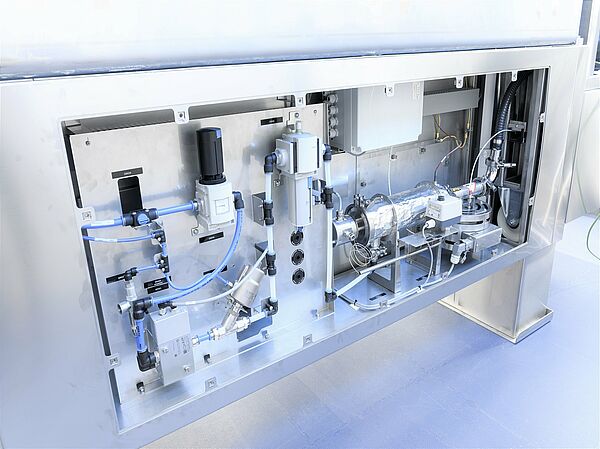

Fully automatic leak test of system tightness, integrated compressed air driven H2O2 gas generator for fully automatic bio- decontamination, process monitoring and logging help to ensure continuous environmental control as well as complete operator and process safety.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/3/c/csm_DSC00524_791b2b8d6d.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/6/9/csm_Einflussfaktoren_CO2_Fu%C3%9Fabdruck_3724c2eaf6.png)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/5/b/csm_scientists-working-in-laboratory-2023-11-27-05-15-50-utc_bf2e0e9300.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/b/0/csm__E6A2843_3729d07404.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/6/4/csm_ortner-infineon-Infineon-Chipfabnew-Villach-inside-0921-7_97276e8d57.jpg)

![[Translate to Englisch:] [Translate to Englisch:] Nebeneinander sitzen drei Personen mit Schutzkleidung. Die vorderste Person schaut durch ein Mikroskop. Über das Bild gelegt sind verschiedene Icons, die so aussehen, als würden sie rund um das Mikroskop schwirren.](/fileadmin/_processed_/9/d/csm_adobestock_327970556_web_db394ed81e.jpg)

![[Translate to Englisch:] [Translate to Englisch:] Stefanie Rud und Josef Ortner](/fileadmin/_processed_/8/5/csm_Stefanie_Rud_und_Josef_Ortner_ec6c1b0ec7.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/5/4/csm_Bild2_da3086f97d.jpg)

Print out

Print out