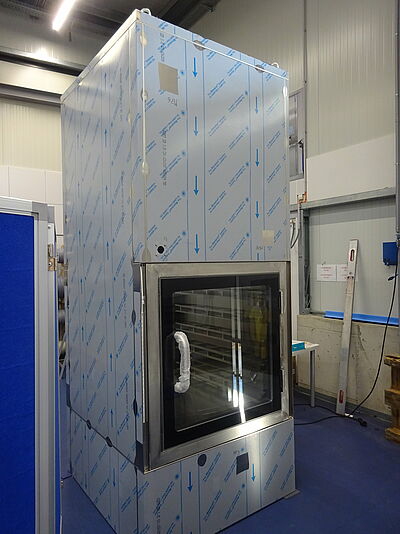

The compact airlock is a powerful - as the name suggests - compact system for the infeed and sterilization of goods, material and equipment.

The environmentally friendly H₂O₂-technology enables an almost unlimited application for material-saving airlock processes.

Print out

Print out