- Safe entry and/ or exit of personnel in protective clothing from a cleanroom

- Effective and fast surface cleaning of personnels clothing

- Removal of pathogens, allergens, or other contaminants and pollutants from personnel and their garments

- Microbiological germ reduction of cleanroom garments

- Safe and reliable cleaning processes

- Demand-specific requirements, e.g. designs suitable for animal areas

Your Requirements

Ortner Solutions

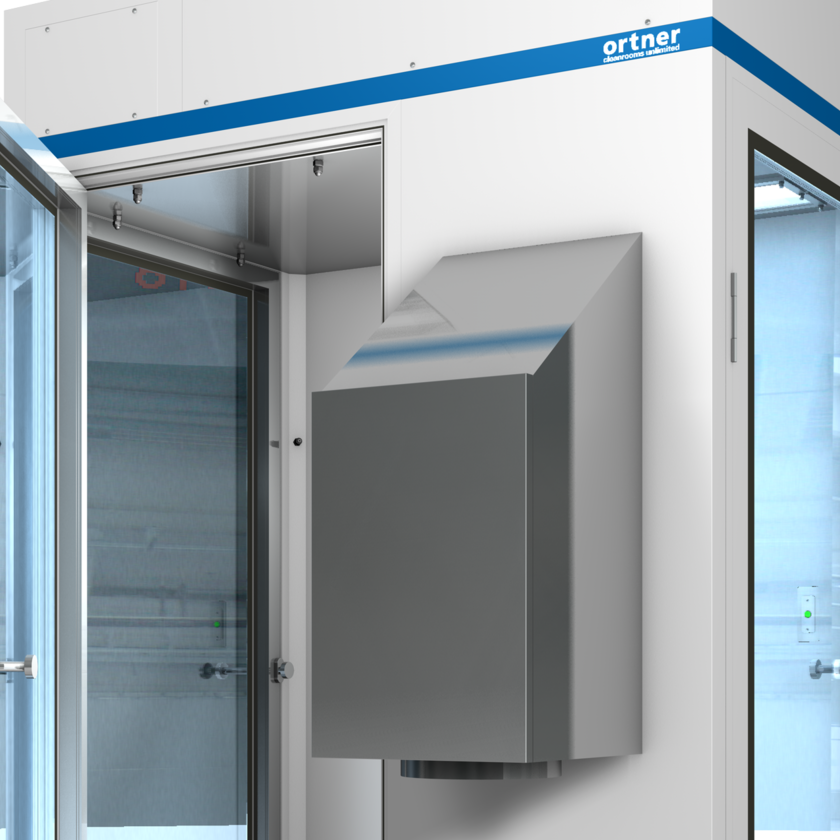

Plug-in, factory- qualified high- performance airlock systems for dry and wet cleaning processes for persons in protective clothing.

Expertise and Understanding of Technology

All Ortner personnel airlocks are designed for reproducible processes.

The nozzle technology used was developed on the basis of simulation results on air flow and particle transport of an extensive research work, in cooperation with the University and Research Center of the Graz University of Technology to ensure efficient particle removal.

Automated and validatable cleaning processes are adapted to their respective requirements.

For wet processes, a fluorescence test is performed to check the quality of cleaning.

Photodynamics for Reduction of Microbiological Germs

The patented PDc technology reduces the amount of microbiological germs as well as the removal of particles in one process.

Ortner PLUS

- Scientifically tested and patented nozzle technology

- Unique process for effective microbiological inactivation of germs on clothing surfaces

- Reproducible processes and automatic procedures

- GMP-compliant and qualified design

- Plug-in systems, uncomplicated integration into existing cleanroom concepts

Print out

Print out