For many special applications, such as foot- and- mouth disease, or the occurrence of certain viruses for which there is still no documented proof of efficacy of H₂O₂-decontamination technology, this still remains the only and practical method.

- EXPERIMENTAL ANIMAL HUSBANDRY

- HIGHER SAFETY AREAS (Bio- Safety Level Laboratory)

- QUARANTINE AREAS

- NICLE AREAS (e.g., hatcheries or equivalent animal housing).

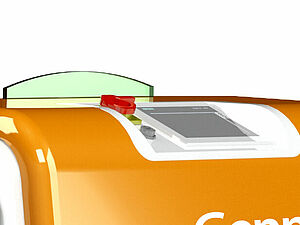

Print out

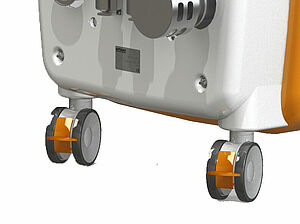

Print out