- Aseptic manufacturing, processing and manipulation of biological materials, active substances, hazardous substances or other highly sensitive products and materials

- Aseptic filling, sterility testing, and processing of biological materials

- Aseptic working conditions with the highest sterility assurance of the product and operators

- Fast and automated bio- decontamination of the isolator chamber

- Seamless protection of product and personnel during handling processes in hospitals, clinical pharmacies

- Demand specific requirements

Your Requirements

Ortner Solution

Highly efficient modular isolator systems with fast and safe automated bio- decontamination system for aseptic and/ or toxic processes.

More Productive Thanks to Industry 4.0 Solutions

Ortner isolators follow the paradigm of integrated innovation:

Recurring processes and tasks are automated, and digital solutions are developed and integrated as needed. By integrating the automated and digital solutions, the processes become faster, more efficient and economically better.

Automated processes with digital solutions

Ortners isolator systems were developed on the basis of our many years of experience with this technology. Successful processes have been continuously developed by us on the basis of extensive research activities and optimized according to the respective application requirements.

From risk minimization to energy efficiency: Ortner isolators convince with diverse system functions

Wherever biohazards are present (e.g. microorganisms, viruses, toxins, etc.), highly hazardous substances are used.

A wide variety of Ortner isolator systems are available to choose from where sterile production must be guaranteed during manufacturing and/ or handling or hormones, cytostatics, and teratogenic substances.

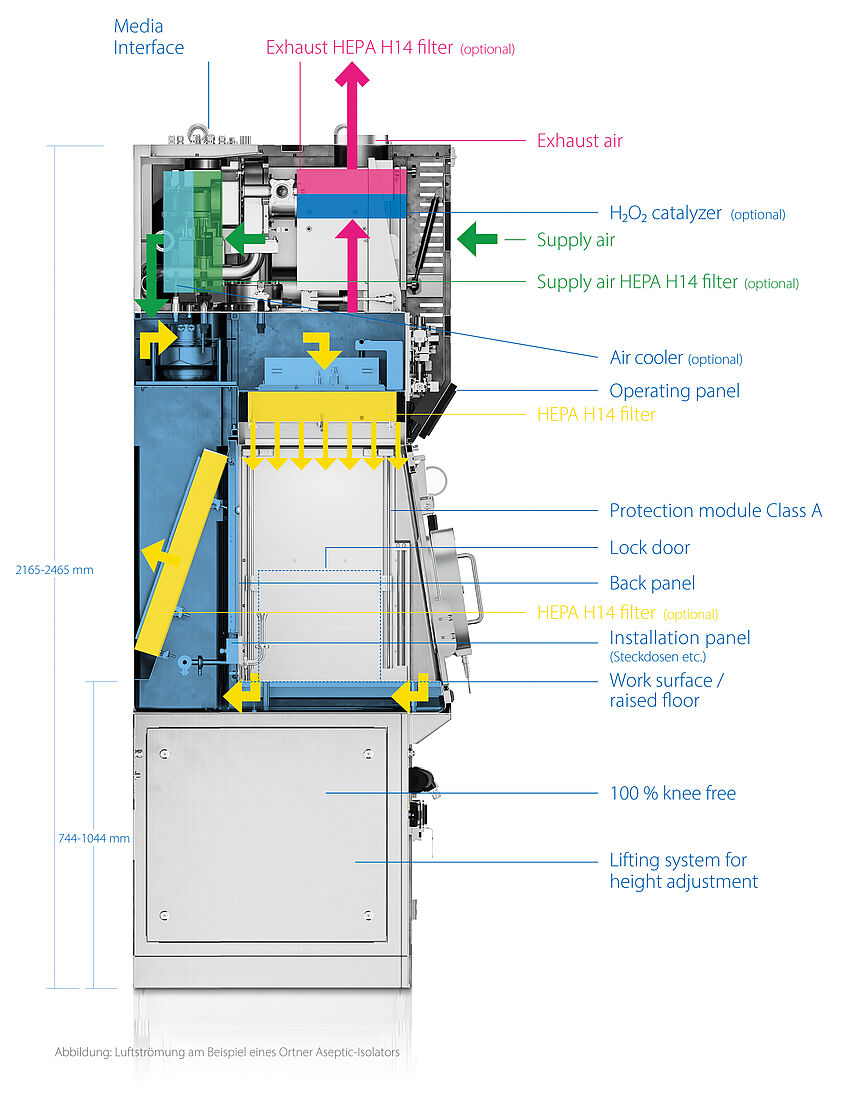

Air Flow Principle

EXHAUST AIR

The exhaust air system extracts the air from the isolator and blows it through a HEPA filter either into the on- site exhaust air system or back into the room. The exhaust fan maintains the air pressure in the isolator chamber at a constant set value, which can be set as positive or negative pressure.

SUPPLY AIR

To ensure a certain air exchange in the isolator, room air is blown into the isolator with the supply air module. Optionally, a HEPA filter can be used if the air in the installation room is of low quality. If cooler temperatures are required in the isolator, a cooler is integrated.

CIRCULATING AIR

A high volume flow is circulated in the isolator and enters the chamber via HEPA filters in the ceiling area. As it does so, the air flows downward with low turbulence, effectively displacing all airborne particles toward the floor.

DOUBLY SAFE

If there is a risk of substance contamination, e.g. by highly active substances, an additional HEPA filter can be used in the recirculating air. The air leaves the work area via an aerodynamically designed exhaust air slot through a raised floor. This allows the air flow to be adapted to various devices installed in the isolator, such as sterile test pumps, scales, etc. The double floor concept is the only way to ensure that the air can be circulated in the isolator. Only with this raised floor concept can the direction and uniformity of the air flow be guaranteed almost to the working surface.

Print out

Print out