The qualification is usually carried out together with the customer. Depending on the respective requirements of the customer, the qualification depth on the part of Ortner- i.e. the share of the entire qualification project to be provided by Ortner- can vary.

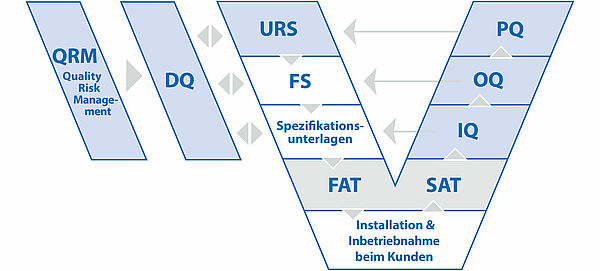

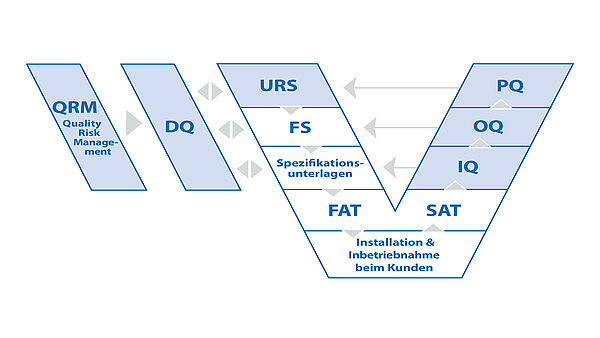

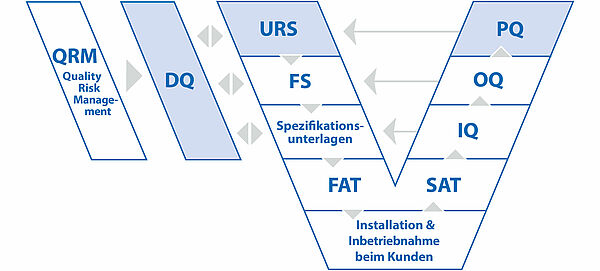

Basically, 3 categories of qualification depth can be distinguished.

Print out

Print out