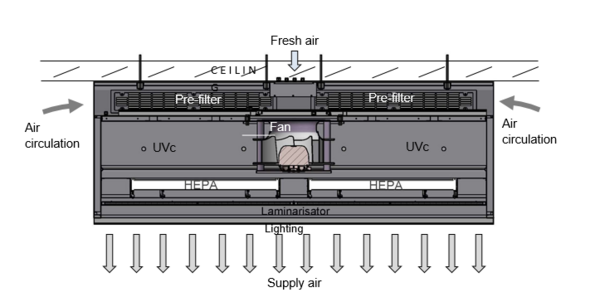

The surface decontamination inside the units and the effective treatment of the filter cells mean that a service life of five to seven years can be achieved for HEPA filter media in microbiologically contaminated areas.

Hurdle Technology

The 2- stage design of the system is referred to as "hurdle technology". The DecAx product line meets the strict requirements in terms of product safety and germ reduction in the processing of meat, delicatessen and sausage products.

Print out

Print out