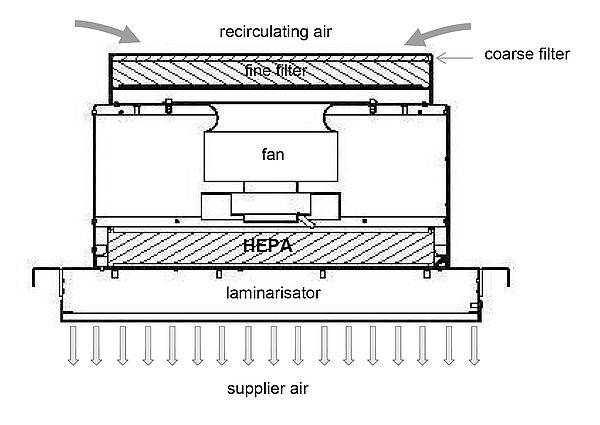

Ambient air is drawn from the room and reintroduced into the room as cleaned and sterilized air directly through the work area.

The production process is thus accompanied and protected by a "clean air cloud" (CleanCloud).

Germ- free environment for airy baked goods.

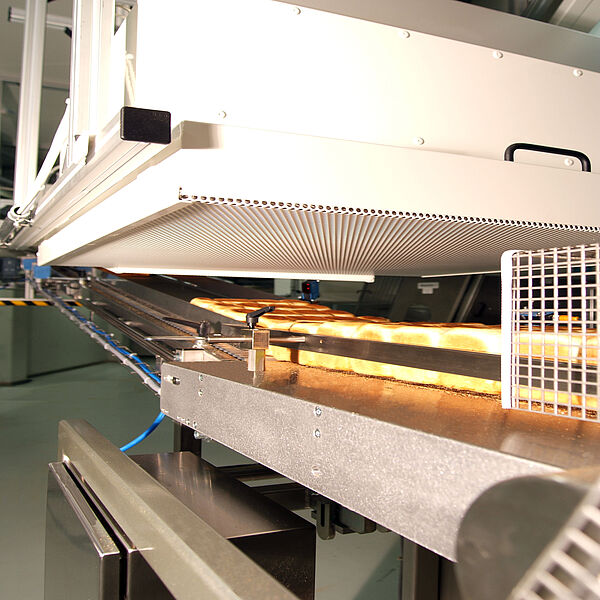

Clean air, safe food. Molds and spores are among the major challenges in food production and processing. CleanCloud prevents recontamination by microorganisms right from the start of production, thus ensuring microbiological safety, especially in the production of baked goods.

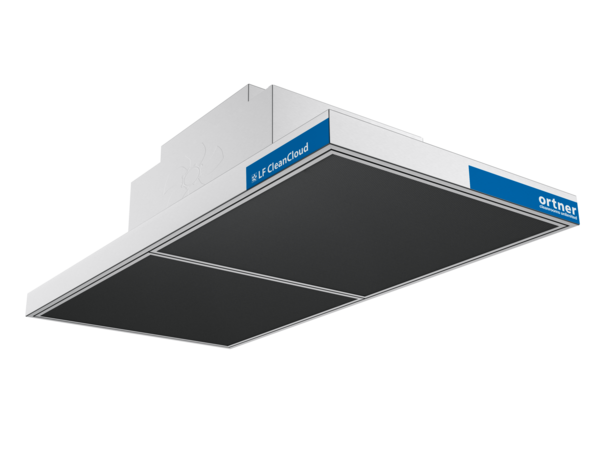

CleanCloud- a cloud of pure air. Ortner's CleanCloud combines sophisticated, intelligent technology with elegant industrial design. As a partial system, it guarantees maximum flexibility when used in production lines.

The specially developed FlowLine module draws ambient air from the room and reintroduces it into the room as purified, sterilized air directly above the work area. In this way, the production process is accompanied and protected by a "clean air cloud" (CleanCloud).

Ambient air is drawn from the room and reintroduced into the room as cleaned and sterilized air directly through the work area.

The production process is thus accompanied and protected by a "clean air cloud" (CleanCloud).

"Laminar flow system" refers to a flow technology in which air masses are cleaned laminarly, i.e. calmly.

The air is sucked in, filtered, and flows out again free of particles and germs.

The Laminarflow CleanCloud guarantees the lowest possible bacterial count (CFU < 1) as well as keeping critical zones clean. In this way, you achieve high product safety in a gentle way - without chemical preservatives or additional thermal processes.

* Hygienic design: good cleanability, no dead spaces, resistant to common cleaning agents V4A -1.4404.

A FlowLine module developed by Ortner