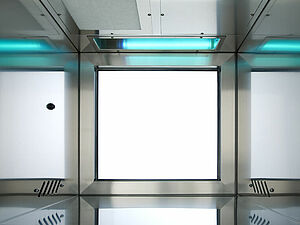

All-glass doors are made of toughened safety glass and are installed on the operating sides of the material transfer hatch.

The material transfer hatch itself contains a control module and an aerosol filter testing device.

The supply and exhaust air is supplied externally. Internal hit-and-miss valves are used to set the pressure.

Print out

Print out