Innovative products and solutions in the laminar flow sector ensure the safe production and packaging of dairy and cheese products: From production lines and machines to processing rooms and service counters.

Especially in critical areas, such as for slicing and packaging cheese products or in ripening rooms, protection against contamination is essential.

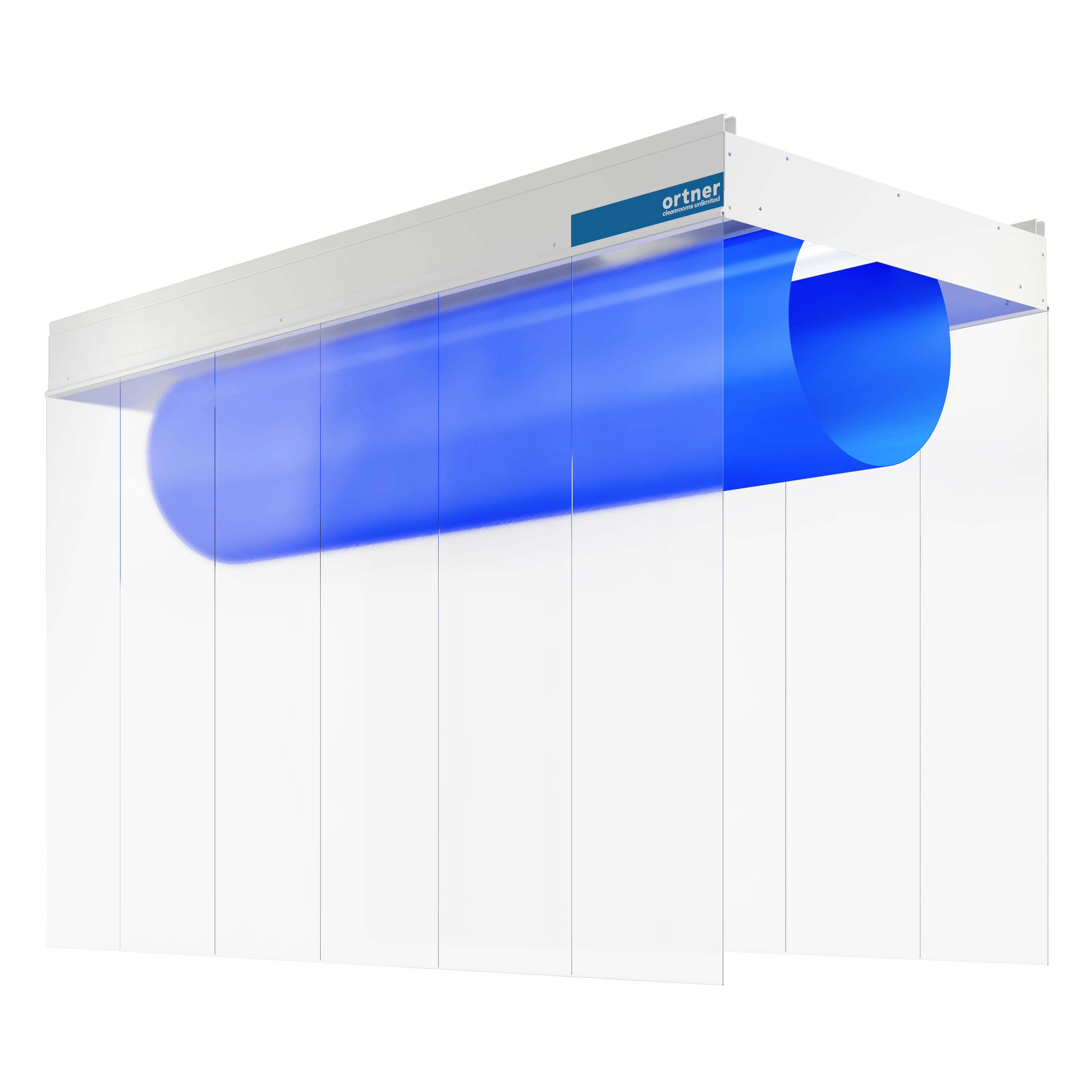

To create a germ- free environment, innovative processes such as UVc surface disinfection and filter technology are used. UVc rays are part of sunlight and disinfect without chemicals or heat. Therefore, the quality of the products is not changed.

Ortner places the highest value on maintaining product quality as well as flexible, needs-based solutions and standards that far exceed those required by law.

Print out

Print out