The fact that automation in process plants, isolators or production-related equipment has always had a high priority in the pharmaceutical industry is nothing new and is part of the custom of good plants.

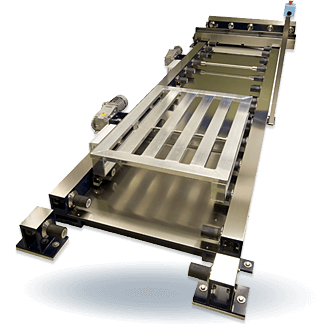

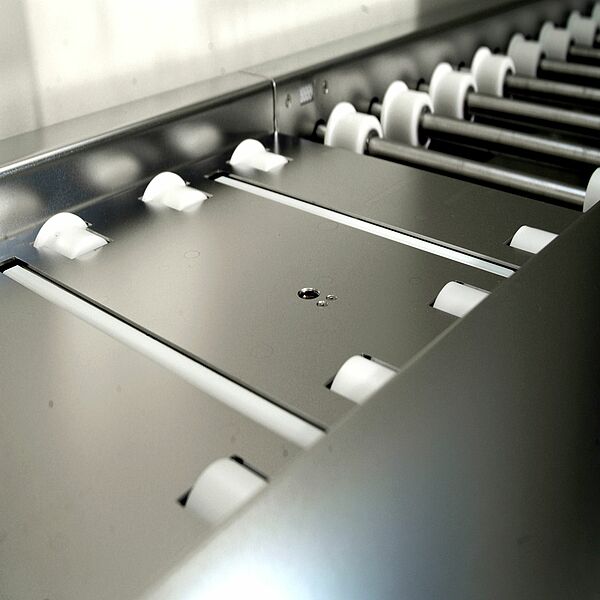

In the extended production environment, automated transport systems are not yet part of everyday equipment. The trend also in the run- up to production plants and systems with a high degree of automation and digitization is clearly visible.

Whether automated logistics systems from storage areas or feeds to test train weighing and mixing stations, or the combination of transport systems with robots, or the use of AGV "Automated Guided Vehicle" systems, we at Ortner deal with all techniques of this kind. Very competent partners from our networks support us in challenging tasks.

Print out

Print out