Ortner decontamination nozzles are designed according to the latest CFD simulations.

The resulting optimized air and gas flow enables even faster and more efficient cycle times for room decontamination.

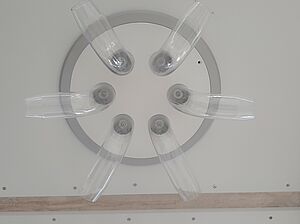

Intelligent Gas Distribution Nozzle STAR

Digitally controlled decontamination nozzle.

Higher decontamination efficiency. The fully digitally controlled STAR decontamination nozzle combines in- depth knowledge of nozzle technology with a clear understanding of application- specific needs.

STAR provides significant improvement in the efficiency of room decontamination and therefore meets the highest requirements. Ortners patented CFD- optimized design ensures the best possible circulation of air in the room.

Controlled via ISU or HTML web server, each nozzle outlet can be controlled individually and completely digitally. The processed data is transferred to a higher- level control system via an OPC interface. Operation of the nozzle, such as parameterization and control, is carried out via an Ortner H₂O₂ Gas Generator (ISU) or via an HTML web server.

Ortner decontamination nozzles are designed according to the latest CFD simulations.

The resulting optimized air and gas flow enables even faster and more efficient cycle times for room decontamination.

This digitally controlled Intelligent Gas Distribution Nozzle STAR combines in- depth knowledge of nozzle technology with a clear understanding of application- specific needs.

This nozzle achieves significantly better efficiency and therefore meets the high requirements of any room decontamination.

System Requirements

The Solution: Ortner Technology & Know-How. Complete. Diverse. Clean.