Cytostatic isolators from Ortner ensure safe working conditions according to GMP Class A.

The special air guidance and handling via glove intervention guarantee safe separation of operator and process.

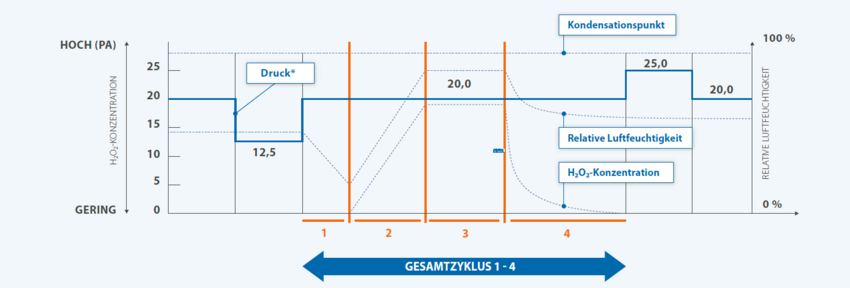

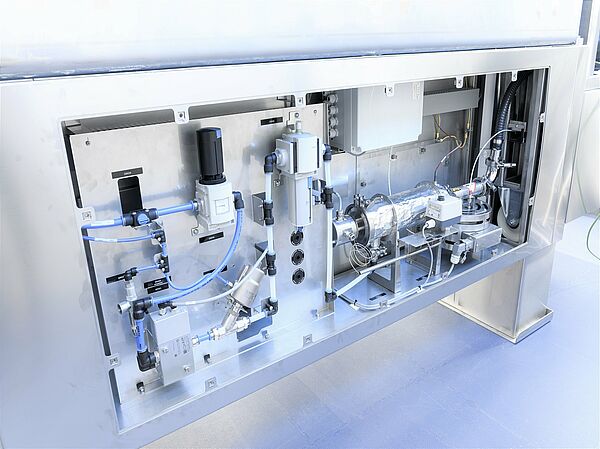

Fully automatic leak test of system tightness, integrated compressed air driven H₂O₂-gas generator for fully automatic bio- decontamination, process monitoring and logging help to ensure continuous environmental control as well as complete operator and process safety.

Print out

Print out