Over 15 years of research on different disinfection and decontamination processes form the basis of our know- how.

For example, the gaseous hydrogen peroxide decontamination (H₂O₂) developed by Ortner is considered a true milestone in the microbiological field of cleanroom technology- and a major contribution to a turning point in medical and pharmaceutical decontamination technology.

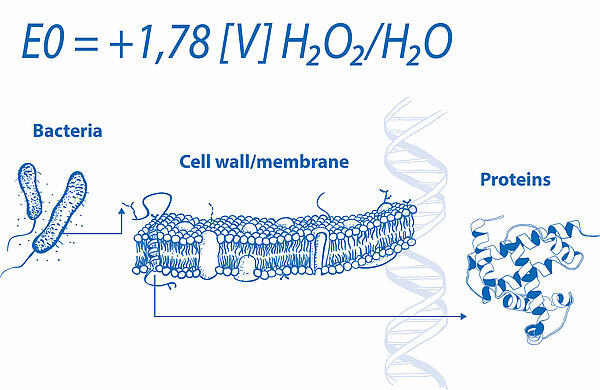

H₂O₂ decontamination is the disinfection by means of vaporized hydrogen peroxide. This system is both safer and more environmentally friendly than previous methods such as those using formaldehyde.

The advantages are clear: easier applicability for users and an important contribution to environmental protection.

The H₂O₂ decontamination technology can be used almost everywhere and is effective even where other methods cannot be used or are very difficult to use. Preferably it is used

in the pharmaceutical industry, medical technology, animal breeding, in hospitals, in biochemical testing facilities and in the food industry.

Print out

Print out