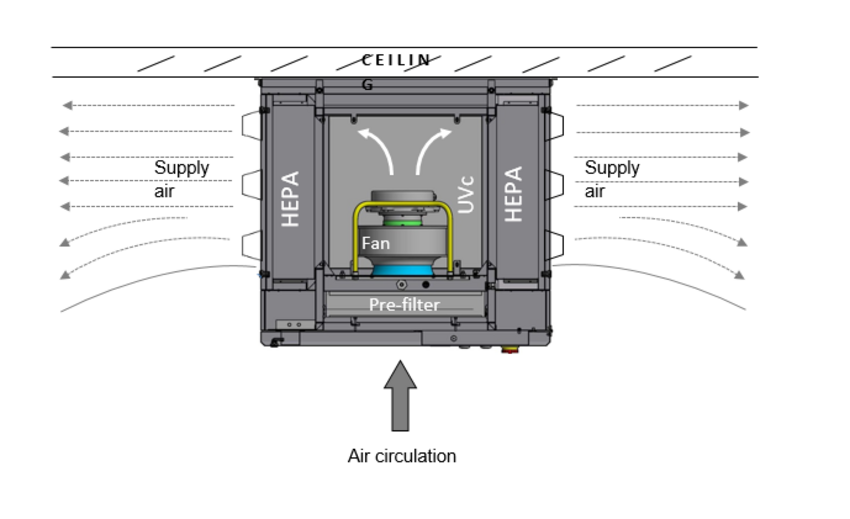

To minimize microbiological risks, the hygienic recirculating air coolers feature not only a powerful cooling coil but also two filter stages (1x coarse filter and 1x HEPA filter) and integrated UVc disinfection.

Hygiene Recirculating Air Cooler

For increased hygiene requirements

The alternative to conventional room air coolers. Ortners hygienic recirculating air coolers are clean room systems that have been specially developed for increased hygiene requirements.

Thanks to their filter technology and sterilization technology, they are a real alternative to conventional room air coolers. The area of application ranges from general cold rooms to cooled production rooms.

Principle of low- turbulence mixed flow. Designed as a room protection concept, the Hygiene recirculating air coolers operate on the principle of low- turbulence mixed flow. The flow generated in this way is ideally suited to optimally distribute the cooled air in the surrounding area without generating high turbulence or strong drafts at specific points.

Ortner PLUS

- Established room protection concept for increased production safety

- CFU < 50/ 100 m³ room volume achievable

- Microbiological protection concept through cooling, HEPA filter and integrated UVc disinfection

- Optimized flow pattern ¬- ideal cooling air distribution with reduced turbulences

- Can be combined with other systems such as Aseptic FFU, DecAx and Clean Cloud

- Ready- to- plug- in and factory- qualified system

- Complies with GMP and HACCP guidelines

Highest Safety For Food Production

Technical Data

Options

* Hygienic design: good cleanability, no dead spaces, resistant to common cleaning agents V4A -1.4404.

High Cooling Capacity

Hygienic recirculating air coolers are purely room-internal recirculating air systems (without air ducts or a connection to infrastructure ventilation systems). In conjunction with air dehumidification systems or when used in rooms with a relative humidity < 50%, media temperatures of -7 °C can be used. This means that low room temperatures or high cooling capacities can also be achieved.

We deliver what you actually need

Contact us, our experienced team will be happy to advise you.

Print out

Print out