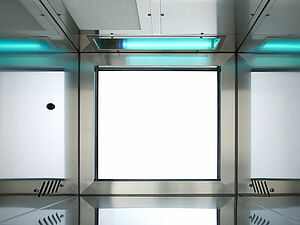

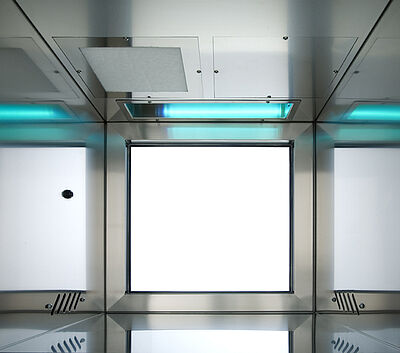

For cleanrooms from ISO Class 4 as well as GMP Class B.

A control module and aerosol filter testing device is integrated into the material transfer hatch. The supply and exhaust air is supplied externally.

The exhaust air volume (pressure inside the material transfer hatch), as well as the respective purging and locking times, are freely selectable.

Print out

Print out