The best possible protection for your personnel

The GMP- compliant personnel shower for wet processes reduces the risk of contamination or carryover of hazardous substances and offers optimum personnel protection.

All Ortner personnel showers are designed for reproducible processes.

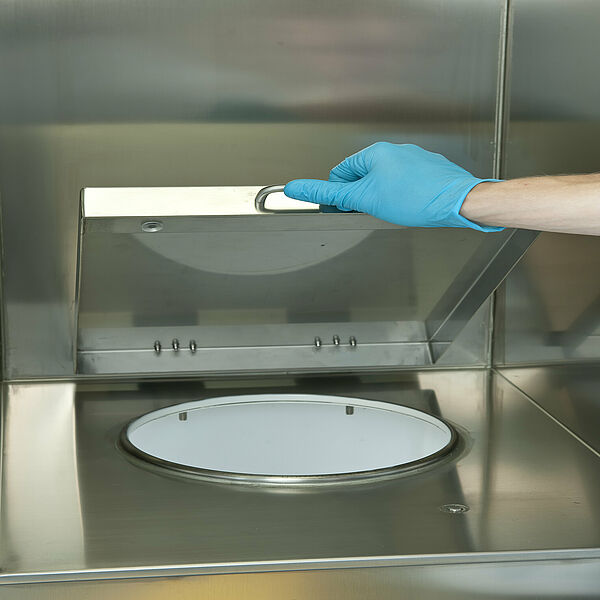

A fluorescence test is performed to verify the quality of cleaning for wet processes.

Print out

Print out